CNC TURNING, MILLING &

EDM MACHINES

MC Machinery MCV Series

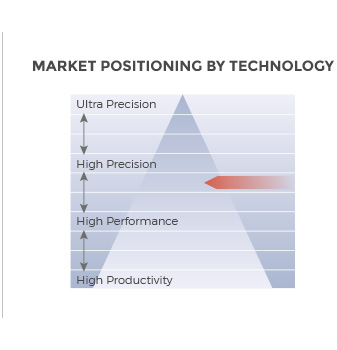

Economy Line - 12,000 rpm, Linear Ways, Mitsubishi M80 CNC

When quality dominates the conversation but price matters

MCV-600 to MCV-3000B

MCV Configuration

| 12,000 rpm, 40 Taper Big Plus, 20/15 HP, 32 ATC, Mitsubishi M80 CNC | BIG PLUS | Ball Bearing Linear Ways  | |

|---|---|---|---|

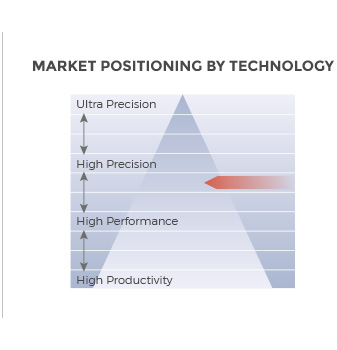

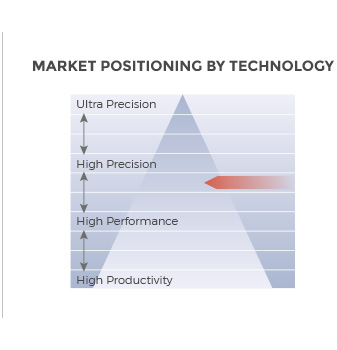

| Model | Travels X x Y x Z | Market Price Positioning | Value Proposition |

| MCV-600 | 24.0 x 16.1 x 21.3 | ||

| MCV-800 | 31.5 x 17.7 x 21.3 | ||

| MCV-1000 | 40.2 x 20.1 x 23.6 | ||

| MCV-1200 | 47.2 x 23.6 x 26.6 | ||

| MCV-1400 | 55.1 x 25.6 x 26.6 | ||

MCV-B Configuration

| 10,000 rpm, 50 Taper Big Plus, Box Ways on Z-axis, ZF Gear Box High Torque, 32 ATC, Mitsubishi M80 CNC | BIG PLUS | Roller Ways | |

|---|---|---|---|

| Model | Travels X x Y x Z | Market Price Positioning | Value Proposition |

| MCV-1000B | 40.2 x 20.1 x 23.6 | ||

| MCV-1200B | 47.2 x 23.6 x 26.6 | ||

| MCV-1400B | 55.1 x 25.6 x 26.6 | ||

| MCV-1600B | 63.0 x 35.4 x 31.5 | ||

| MCV-2000B | 78.7 x 35.4 x 31.5 | ||

| MCV-3000B | 118.1 x 39.4 x 29.5 | ||

Contact us for more info or quote request:

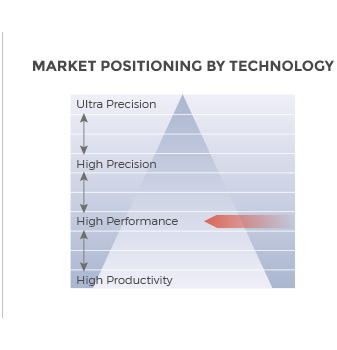

MC Machinery DV Series

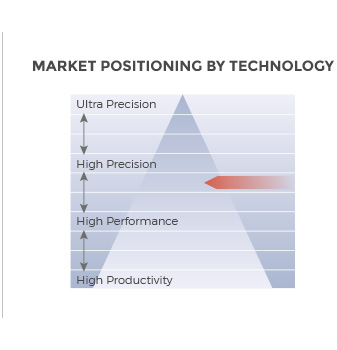

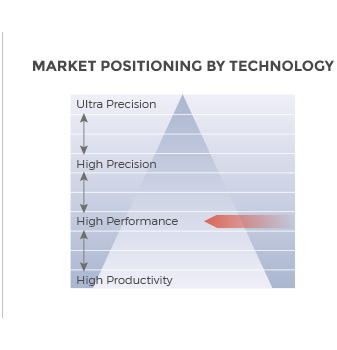

High Performance - 15,000 rpm, Roller Ways, Mitsubishi M80 CNC

When performance dominates the conversation but price matters

DV-800 to 2000

| 15,000 rpm, 40 Taper BIG PLUS, 15/10 HP, 32 ATC (40 opt), M80 Mitsubishi CNC | BIG PLUS | Roller Ways | ||

|---|---|---|---|---|

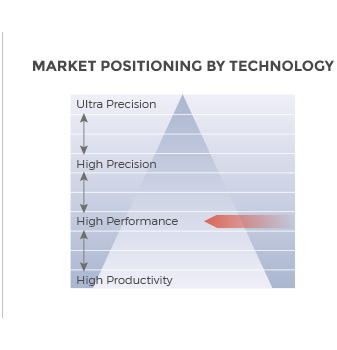

| Model | Travels X x Y x Z | Market Price Positioning | Value Proposition | |

| DV-800* | 31.5 x 19.7 x 21.3 | |||

| DV-1000 | 40.2 x 22 x 23.6 | Testimonial... | ||

| DV-1200 | 47.2 x 23.6 x 26.6 | |||

| DV-1400 | 55.1 x 31.5 x 29.1 | |||

| DV-1600 | 63.0 x 35.4 x 31.5 | |||

| DV-2000 | 78.7 x 35.4 x 31.5 | |||

Contact us for more info or quote request:

MC Machinery TV Series

Drill / Tap / Mill - 24,000 rpm, 2,400 ipm Rapids, Mitsubishi M80 CNC

The TV Series is one of the fastest milling, drilling, tapping machine in the industry. With 24,000 rpm, 2,400 inch/min rapids and 0.9 second tool change, this machine is perfect for production applications.

TV-500 / TV-700

| 24,000 rpm, BBT30, 21 ATC, 0.9 second tool change, 2,400 ipm rapids, Mitsubishi M80 CNC | BIG PLUS | Ball Bearing Linear Ways  | ||

|---|---|---|---|---|

| Model | Machine Travels X x Y x Z | Spindle Std/Opt | Market Price positioning | Value Proposition |

| TV-500 | 19.7 x 15.7 x 13.0 | 24k / 20k, 12k | ||

| TV-700 | 27.6 x 15.7 x 13.0 | 24k / 20k, 12k | ||

Contact us for more info or quote request:

MC Machinery MC Series

Economy Line - 15,000 rpm, Roller Ways, Heidenhain TNC-640 CNC

When Capabilities meet Size and Value

This series of machines with Heidenhain Control has been designed for Job Shops and Mold Makers doing 5 sided machining and/or simultaneous 5 axis. Standard with a 15,000 RPM Direct Drive 40 taper Big Plus Spindle or several different optional HSK spindles. Blum Part Probe and Tool Laser Measurement will greatly reduce your set-up time.

MC-4000 shown with 6 position automatic pallet changer and 120 position tool changer

MC-4000 / 6000 / 8000

| 15,000 rpm, 40 Taper Big Plus, 40/15 HP, 48 ATC, Roller Ways, Heidenhain TNC-640 | BIG PLUS | Laser Tool Measuring | |||

|---|---|---|---|---|---|

| Model | Machine Travels X x Y x Z | Spindle Std/Opt | Table Ø | Market Price positioning | Value Proposition |

| MC-4000 | 15.7 x 13.8 x 13.8 | 15k / 20k, 24k | 17.7 & 12.6 | ||

| MC-6000 | 24.4 x 20.5 x 18.1 | 15k / 20k, 24k | 25.6 & 19.7 | ||

| MC-8000 | 31.5 x 35.4 x 24.4 | 12k / 15k, 20k, 24k | 31.5 | ||

Contact us for more info or quote request:

OPS Ingersoll Eagle V Series

Dynamically Balanced - 42,000 rpm, Roller Ways, Heidenhain TNC-640

The OPS Ingersoll Eagle made in Germany is the Gold Standard for High Precision Surfacing for the most demanding Mold Shops. Outstanding Dynamics with 42,000 or 36,000 RPM spindle, Thermal Compensation, Glass Scales on all axis and comes automation ready. The only Dual Gantry Drive 5-Axis with 2 ball screws and 2 glass scales on both X & Y axis. The Heidenhain TNC-640 control has industry leading 5,000 block look ahead and 120,000 block per minute processing speed.

Eagle V5 / Eagle V9

| HSK Taper, ATC V5-32 / V9-72 (100 opt), Polymer Concrete Base, Roller Ways, Kinematics Software | Laser Tool |  | ||||

|---|---|---|---|---|---|---|

| Model | Travels X x Y x Z | Spindle Std/Opt | Market Price Positioning | Value Proposition | ||

| Eagle V5 | 21.6 x 15.7 x 15.7 | 42k/36k | More Spec... | Testimonial... | ||

| Eagle V9 | 31.5 x 23.6 x 19.7 | 36k/42k,26k,18k | More Spec... | |||

Contact us for more info or quote request:

Roku-Roku 20 Horsepower Series

Ultra Rigid - 30,000 rpm / 20 HP, Direct Hard Carbide Milling, Fanuc 31i-B5

Most versatile HSM for heavy duty cutting of hardened tool steel & carbide tungsten with mirror finish.

High-rigidity, bridge-type monoblock structure allows high-speed, high-precision machining while the minimized distance between guide surface and spindle center provides greater stability. This machine is setting the new standard in Carbide Tunsten roughing and finishing.

CEGA SS-300 / VS-652 II / ZEUS-86

| 30,000 rpm HSK-E40, 20/30 ATC (60 opt), Roller Ways, Pneumatic Counter Balanced Z-Axis, Thermal Comp | Laser Tool |  | |||

|---|---|---|---|---|---|

| Model | Travels X x Y x Z | Spindle | Market Price Positioning | Value Proposition | |

| CEGA SS-300 | 20.0 x 16.1 x 12.2 | 30k | More Spec... | ||

| VS-652 II | 23.6 x 19.7 x 15.7 | 30k | More Spec... | ||

| ZEUS-86 | 31.5 x 23.6 x 15.7 | 25k | More Spec... | ||

Contact us for more info or quote request:

Roku-Roku Linear Motor Series

Sub Micron - 60,000 rpm, Hard Milling & Jig Grinding, Fanuc 31i-B5

When Accuracy Matters Most: Linear Motor, Temperature Control and Perfect Craftmanship

The Ultra Precision Micro Fine machining center, 1 Micron Cutting Accuracy, with a 60,000 RPM Spindle driven by a Fanuc 31i-B5 CNC is also capable of Jig Grinding and cutting Carbide Tungsten. Its Active Heat Isolation System has been implemented for the most uniform temperature of all the machine components (16 Thermal Sensors) to monitor and maintain the best accuracy possible.

Android II / Vision 300 / Vision 600 / VEGA-600

| 60,000 rpm HSK-E25, 40 ATC, Active Heat Isolation System, M-Kit Temp Monitoring, Super Tool Measurement | Laser Tool |  | |||

|---|---|---|---|---|---|

| Model | Travels X x Y x Z | Spindle | Market Price Positioning | Value Proposition | |

| Android II | 17.7 x 13.8 x 7.9 | 60k / 150k air | More Spec... | ||

| Vision 300 | 25.6 x 21.6 x 11.8 | 30k / 150k air | More Spec... | ||

| Vision 600 | 25.6 x 21.6 x 11.8 | 60k / 150k air | |||

| New Linear Motor machine equipped with Hydro-Static Guide Technology for smoother motion system enabling great surface finish | |||||

|---|---|---|---|---|---|

| Model | Travels X x Y x Z | Spindle Std/Opt | Market Price Positioning | Value Proposition | |

| VEGA-600 | 16.1 x 13 x 7.9 | 60k / 150k air | Contact us for Spec | ||

Contact us for more info or quote request:

Roku-Roku HC Series

Dual Purpose - 32,000 rpm, Steel & Graphite, Fanuc 31i-B5

When cutting Electrodes Accurately and with Ultimate Reliability due to the most effective dust removal system.

The HC series is the ultimate dual-purpose machine for Hard Milling and Graphite cutting to the tightest tolerances. 32,000 and 40,000 rpm spindles combine best material removal rates with high RPM for small cutting tools. This machine was designed from the ground up to incorporate the best graphite protection and dust removal to protect the spindle insuring long spindle life as well as all machine components.

HC Series

| Grease Packed 32,000 rpm HSK-E40, 20/30 ATC (40, 60 opt), Roller Ways, Thermal Comp, Dust Collection & Protection | Laser Tool |  | |||

|---|---|---|---|---|---|

| Model | Travels X x Y x Z | Spindle Std/Opt | Market Price Positioning | Value Proposition | |

| HC-435 II | 16.1 x 13.0 x 7.9 | 36k | More Spec... | ||

| HC-548EX | 18.1 x 14.1 x 10.2 | 32k | More Spec... | ||

| HC-658 II | 23.6 x 19.7 x 15.7 | 32k/40k | More Spec... | ||

| HC-878 | 33.5 x 29.5 x 16.0 | 32k/40k | More Spec... | ||

Contact us for more info or quote request:

Roku-Roku MEGA SS Series

Mirror Finish / Micro Tool - 40,000 rpm, Flood or Dry, Fanuc 31i-B5

When cutting wet is your key to optimum performance

The Roku-Roku MEGA SS-400 is an exceptionally well-built machine tool coupled with the Fanuc 31i-B5 controller. Roku’s Super PCIII optimizes velocity and acceleration/deceleration through the use of a super high-speed processor with AI Contour Control II, Nano Smoothing and look ahead block expansion.

MEGA SS-400/600

| 40,000 rpm HSK-E25, 20 ATC (40, 60 opt), Roller Ways, Pneumatic Counter Balanced Z-Axis, Thermal Comp | Laser Tool |  | |||

|---|---|---|---|---|---|

| Model | Travels X x Y x Z | Spindle | Market Price Positioning | Value Proposition | |

| MEGA SS-400* | 16.1 x 13.0 x 7.9 | 40k | More Spec... | ||

| MEGA SS-600 | 16.1 x 13.0 x 7.9 | 60k | More Spec... | ||

Contact us for more info or quote request:

MC Machinery DM-G Series

Economy Line - 24,000 rpm, Steel & Graphite, Mitsubishi M830 CNC

When you need to exceed expectations but price matters

The DM-G series is a High Precision Graphite Mill with a 24,000 RPM HSK-E40 spindle, Ultra High Speed Machining/ High Accuracy Mode, Thermal Compensation and XYZ Glass Scales. Blum Tool length/ Diameter Laser is Standard. Double Graphite protection way-covers and Dust Collection System.

DM-800G / DM-1200G

| Grease Packed 24,000 rpm HSK-E40, 24 ATC, Roller Ways, Z-Axis Thermal Comp, Glass Scales, Dust Collection System | Laser Tool Measuring  | Roller Ways  | ||||

|---|---|---|---|---|---|---|

| Model | Travels X x Y x Z | Dist. Table / Spin. | Market Price Positioning | Value Proposition | ||

| DM-800G | 31.5 x 19.7 x 21.3 | 5.9 - 27.2 | More Spec... | Testimonial... | ||

| DM-1200G | 47.2 x 23.6 x 26.6 | 3.9 - 30.5 | More Spec... | |||

Contact us for more info or quote request:

OPS Ingersoll Eagle V Series 5-Axis

Dynamically Balanced - 42,000 rpm, Roller Ways, Heidenhain TNC-640

German Gold Standard for Surfacing, Dynamic Accuracy and Rigidity

The OPS Ingersoll Eagle made in Germany is the Gold Standard for High Precision Surfacing for the most demanding Mold Shops. Outstanding Dynamics with 42,000 RPM spindle, Thermal Compensation, Glass Scales on all Axis. The only Gantry design with double ball screws system on XY axis. Industry leading TNC 640 Heidenhain Control with 500 blocks Lookahead.

Eagle V5 / Eagle V9

| Polymer Concrete Bridge Mill, High Dyanmic Accuracy cutting mode and Rigidity, Ultra Accurate Mode and Functions, Toolchanger from 72 to 110 Tools, Heidenhein T640 CNC | Laser Tool |  | ||||

|---|---|---|---|---|---|---|

| Model | Travels X x Y x Z | Spin/ OPT | Table Ø | Market Price Positioning | Value Proposition | |

| Eagle V5 | 21.6 x 15.7 x 15.7 | 42k/36k | 15.7 | More Spec... | ||

| Eagle V9 | 31.5 x 23.6 x 19.7 | 36k/26k/18k | 23.6 | More Spec... | ||

Contact us for more info or quote request:

Roku-Roku Mega / Cega

Mirror Finish / Micro Tool - 40,000 rpm, Flood or Dry, Fanuc 31i-B5

When Accuracy Matters Most: Linear Motors, Temperature Control and Perfect Craftmanship

Micro Milling and Micro Drilling with the highest degree of accuracy for ultra thin wall thickness with micro drills.

Cega SS / Mega SSS

| Spec communes à me donner | Laser Tool |  | ||||

|---|---|---|---|---|---|---|

| Model | Travels X x Y x Z/Z Clearance | Spin/Opt | Max Part Ø (.067 above) | Market Price Positioning | Value Proposition | |

| CEGA SS | 20.0 x 16.1 x 12.2/24.6 | 30k | 15.7 | More Spec... | ||

| MEGA SSS | 16.1 x 13.0 x 7.87/8.94 | 40k/60k | 6.14/7.87 | More Spec... | ||

Contact us for more info or quote request:

OPS Ingersoll Eagle V Series 5-Axis

Dynamically Balanced - 42,000 rpm, Roller Ways, Heidenhain TNC-640

The OPS Ingersoll Eagle made in Germany is the Gold Standard for High Precision Surfacing for the most demanding Mold Shops. Outstanding Dynamics with 42,000 RPM spindle, Thermal Compensation, Glass Scales on all Axis. The only Gantry design with double ball screws system on XY axis. Industry leading TNC 640 Heidenhain Control with 500 blocks Lookahead.

Eagle V5 / Eagle V9

| HSK Taper, ATC V5-32 / V9-72 (100 opt), Polymer Concrete Base, Roller Ways, Kinematics Software | Laser Tool |  | ||||

|---|---|---|---|---|---|---|

| Model | Travels X x Y x Z | Spindle Std/Opt | Market Price Positioning | Value Proposition | ||

| Eagle V5 | 21.6 x 15.7 x 15.7 | 42k/36k | More Spec... | Testimonial... | ||

| Eagle V9 | 31.5 x 23.6 x 19.7 | 36k/42k,26k,18k | More Spec... | |||

Contact us for more info or quote request:

MC Machinery DM-G Series

Economy Line - 24,000 rpm, Steel & Graphite, Mitsubishi M830 CNC

When you need to exceed expectations but price matters

The DM-G series is a High Precision Graphite Mill with a 24,000 RPM HSK-E40 spindle, Ultra High Speed Machining/ High Accuracy Mode, Thermal Compensation and XYZ Glass Scales. Blum Tool length/ Diameter Laser is Standard. Double Graphite protection way-covers and Dust Collection System.

DM-800G / DM-1200G

| Grease Packed 24,000 rpm HSK-E40, 24 ATC, Roller Ways, Z-Axis Thermal Comp, Glass Scales, Dust Collection System | Laser Tool Measuring  | Roller Ways  | ||||

|---|---|---|---|---|---|---|

| Model | Travels X x Y x Z | Dist. Table / Spin. | Market Price Positioning | Value Proposition | ||

| DM-800G | 31.5 x 19.7 x 21.3 | 5.9 - 27.2 | More Spec... | Testimonial... | ||

| DM-1200G | 47.2 x 23.6 x 26.6 | 3.9 - 30.5 | More Spec... | |||

Contact us for more info or quote request:

Roku-Roku HC Series

Dual Purpose - 32,000 rpm, Steel & Graphite, Fanuc 31i-B5

The HC series is the ultimate dual-purpose machine for Hard Milling and Graphite cutting to the tightest tolerances. The 36,000 rpm spindles combines best material removal rates with high RPM for small cutting tools. This machine was designed from the ground up to incorporate the best graphite protection and dust removal to protect the spindle insuring long spindle life as well as all machine components.

HC Series

| Grease Packed 32,000 rpm HSK-E40, 20/30 ATC (40, 60 opt), Roller Ways, Thermal Comp, Dust Collection & Protection | Laser Tool |  | |||

|---|---|---|---|---|---|

| Model | Travels X x Y x Z | Spindle Std/Opt | Market Price Positioning | Value Proposition | |

| HC-435 II | 16.1 x 13.0 x 7.9 | 36k | More Spec... | ||

| HC-548EX | 18.1 x 14.1 x 10.2 | 32k | More Spec... | ||

| HC-658 II | 23.6 x 19.7 x 15.7 | 32k/40k | More Spec... | ||

| HC-878 | 33.5 x 29.5 x 16.0 | 32k/40k | More Spec... | ||

Contact us for more info or quote request:

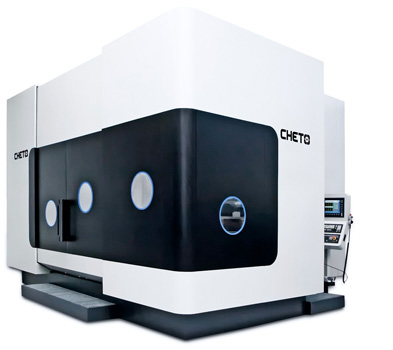

Cheto CC

CC 1000

| Model | Market Price Positioning | Proposition Value | ||||

| CC 1000 | More Spec... | |||||

Contact us for more info or quote request:

Cheto IXN Series

IXN Series

| Model | Market Price Positioning | Proposition Value | ||||

| IXN 1000 | More Spec... | |||||

| IXN 2000 | More Spec... | |||||

| IXN 3000 | More Spec... | |||||

Contact us for more info or quote request:

Cheto MT Series

MT Series

| Model | Market Price Positioning | Proposition Value | ||||

| MT 1500 | More Spec... | |||||

| MT 2500 | More Spec... | |||||

Contact us for more info or quote request:

Cheto SiC

SiC 650

| Model | Market Price Positioning | Proposition Value | ||||

| SiC 650 | More Spec... | |||||

Contact us for more info or quote request:

Your message

Mitsubishi MV-S Series

High Productivity - Linear Shaft Motors, Glass Scales, 50% Wire Savings

When technological innovations drives quality & price to your advantage

The MV-S Series of Wire EDM machine includes advanced features such as non-contact Linear Shaft Motors, Auto-Thread and Re-Thread at the wire breakage point, multiple job processing software, 360 monitoring software and remote diagnostic. With 50% less wire usage, the MV series has the lowest operating cost in the industry. Max cutting height is 30”.

MV-S Series

| .004-.012" (.010 std), Linear Shaft Motors & Glass Scales on X,Y, 10 Year Positioning Warranty | Linear Shaft Motor | ||||

|---|---|---|---|---|---|

| Model | Travels X x Y x Z | Market Price Positioning | Value Proposition | ||

| MV1200-S | 15.7 x 11.8 x 8.7 | More Spec... | Testimonials... | ||

| MV2400-S | 23.6 x 15.7 x 12.2 | More Spec... | Testimonial... | ||

| MV2400-ST | 23.6 x 15.7 x 16.7 | More Spec... | |||

| MV4800-S | 31.5 x 23.6 x 20.1 Opt 32.0 | More Spec... | |||

Differences between S & R Series

Contact us for more info or quote request:

Mitsubishi MV-R Series

High Accuracy - Linear Shaft Motors, Glass Scales, 50% Wire Savings

The MV-R Series of Wire EDM machine includes advanced features such as non-contact Cylindrical Linear Motor, auto thread and re-thread at the wire breakage point, multiple job processing software, 360 monitoring software and remote diagnostic. By using 50% less wire, this machine is the most economical machine to operate.

MV-R Series

| .004-.012" (.010 std/.002 opt), Linear Shaft Motors & Glass Scales on X,Y,U,V, 10 Year Positioning Warranty | Linear Shaft Motor | |||

|---|---|---|---|---|

| Model | Travels X x Y x Z | Market Price Positioning | Value Proposition | |

| MV1200-R | 15.7 x 11.8 x 8.7 | More Spec... | ||

| MV2400-R | 23.6 x 15.7 x 12.2 | More Spec... | ||

| MV4800-R | 31.5 x 23.6 x 12.2 | More Spec... | ||

Differences between S & R Series

Contact us for more info or quote request:

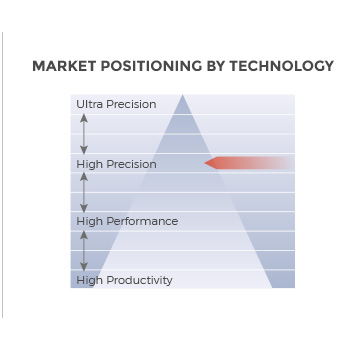

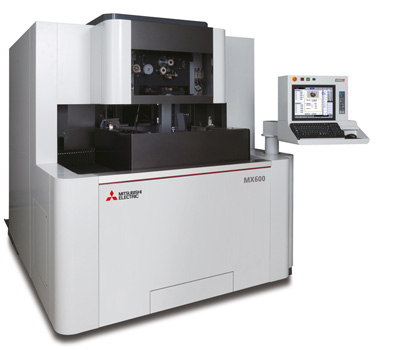

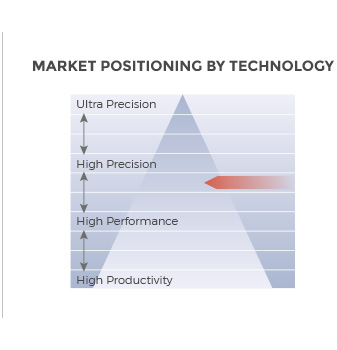

Mitsubishi MX600

Ultra Precision - Oil Machine, .001" Wire, Linear Shaft Motors, 1.4 µ" Ra possible

This machine has been designed for the most demanding applications requiring optimum accuracy in positioning as well as the geometry to be cut. Capable of using down to .0008" wire with automatic threading. The most accurate machine in the market backed up by the best customer service in the business.

MX600

| .0008-.008", Linear Shaft Motors & Glass Scales on X,Y,U,V, 10 Year Positioning Warranty, Ultra-High Accuracy Linear Guides, Fluid Temp Controlled Casting, Granite Table Base | ||||

|---|---|---|---|---|

| Model | Travels X x Y x Z | Market Price Positioning | Value Proposition | |

| MX600 | 11.8 x 7.8 x 7.0 | More Spec... | ||

Contact us for more info or quote request:

Mitsubishi EA-S Series

Economy Line - Z-Axis Glass Scale, No Flush Machining, C-Axis

When quality dominates the conversation but price matters

The Mitsubishi EA-S Series features all new Power Master GF2 Adaptive Control reduces graphite electrode wear as much as 40%. The new SS Jump 5 optimizes high speed jump acceleration enabling machining without flushing.

EA-S Series

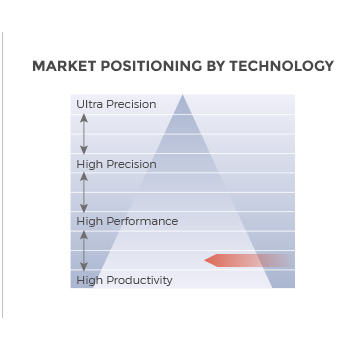

| 3-Sided Drop Tank or Swing Door, 80 Amp (120 Amp opt), 3R or Erowa Chuck, Mitsubishi M700 CNC | ||||||

|---|---|---|---|---|---|---|

| Model | Travels X x Y x Z | Tank Size | Table to Chuck dist. Min~Max | Market Price Positioning | Value Proposition | |

| EA8S | 11.8 x 9.8 x 9.8 | 31.5 x 20.5 x 11.8 | 5.9~15.7 | More Spec... | ||

| EA12S | 15.7 x 11.8 x 11.8 | 35.4 x 27.5 x 17.7 | 7.9~19.7 | More Spec... | ||

| EA12ST | 15.7 x 11.8 x 11.8 | 41.3 x 27.5 x 17.7 | 11.8~23.6 | More Spec... | ||

Contact us for more info or quote request:

Mitsubishi EA-V Series

High Performance for Larger Parts- Z-axis Glass Scale, No Flush Machining, C-Axis

High performance machine with flexible tank configurations for larger work pieces

The Mitsubishi EA-V Series features all new Power Master GF2 Adaptive Control reduces graphite electrode wear as much as 40%. The new SS Jump 5 optimizes high speed jump acceleration enabling machining without flushing.

EA-V Series

| 3-Sided Drop Tank, 80 Amp (120 Amp opt), 3R or Erowa Chuck, Mitsubishi M700 CNC | ||||||

|---|---|---|---|---|---|---|

| Model | Travels X x Y x Z | Tank Size | Table to Chuck dist. Min~Max | Market Price Positioning | Value Proposition | |

| EA28V | 25.6 x 17.7 x 13.8 | 43.3 x 31.9 x 17.7 | 11.8~23.6 | More Spec... | ||

| EA28V-LS | 39.4 x 18.5 x 17.7 | 55.1 x 35.4 x 21.7 | 18.4~36.1 | More Spec... | ||

Contact us for more info or quote request:

Mitsubishi EA-PS Series

High Precision - Low Wear, XYZ Glass Scales, 1.6G Jump, C-Axis

The Mitsubishi EA-PS Series with the new Thermal Buster Compensation System and Z-axis cooling is ideal for tight tolerances in mold & die applications. Featuring multiple fine finish circuits including ultra fine matte and glossy mirror. The all new Power Master GF2 Adaptive Control reduces graphite electrode wear as much as 40%. The new SS Jump 5 with 1.6G acceleration optimizes high speed jump for the fastest machining without flushing.

EA-PS Series

| 3-Sided Drop Tank, Thermal Comp, Cooled Z-Axis, 80 Amp (120 Amp opt), 3R or Erowa Chuck, Mitsubishi M700 CNC | ||||||

|---|---|---|---|---|---|---|

| Model | Travels X x Y x Z | Tank Size | Table to Chuck dist. Min~Max | Market Price Positioning | Value Proposition | |

| EA8PS* | 11.8 x 9.8 x 9.8 | 31.5 x 20.5 x 10.2 | 5.9~15.7 | More Spec... | ||

| EA12PS | 15.7 x 11.8 x 11.8 | 37.0 x 27.5 x 17.7 | 7.9~19.7 | More Spec... | ||

Contact us for more info or quote request:

OPS Ingersoll Eagle G5 Precision

Ultra Precision - Ultra Low Wear, Super Fine Finish with Graphite, C-Axis

The most technologically advanced die sinker ever produced

The Eagle G5 Precision come standard with active thermal compensation and fully enclosed work area. The PowerSpark Generator with ultra low wear technology and super fine surface finish with graphite will outperform any other machine on the market today.

Eagle G5 Precision

| 4-Sided Drop Tank, Enclosed Bridge Design, Retractable Ceiling, Active Thermal Comp, Eagle PowerTec CNC | ||||||

|---|---|---|---|---|---|---|

| Model | Travels X x Y x Z | Tank Size | Table to Chuck dist. Min~Max | Market Price Positioning | Value Proposition | |

| Eagle G5 | 20.7 x 15.7 x 17.7 | 30.3 x 26.4 x 17.3 | 5.3~23.0 | More Spec... | ||

Contact us for more info or quote request:

OPS Ingersoll Gantry Eagle Series

Large Capacity - Low Wear, XYZ Glass Scales, Fine Finish, C-Axis

When surface finish and electrode wear matter on a large machine

The Gantry Eagle Series featuring the all new Eagle PowerTec power supply with the world's first Adaptive Current-Shape generator. Each discharge pulse calculates and creates the ideal current shape to meet the exact discharge requirements at that moment. Eagle PowerTec, combined with Eagle Power Jump, reduces burn time by up to 50 percent, while drastically reducing electrode wear especially in graphite.

Gantry Eagle Series

| 4-Sided Drop Tank, Bridge Design, 110 Amp, ATC Std, Built-in Dielectric Tank for Smallest Floor Space & Fastest Operation, Eagle PowerTec CNC | ||||||

|---|---|---|---|---|---|---|

| Model | Travels X x Y x Z | Tank Size | Table to Chuck dist. Min~Max | Market Price Positioning | Value Proposition | |

| Eagle 800 | 39.4 x 59.4 x 27.5 | 31.5 x 43.3 x 18.9 | 5.3~23.0 | More Spec... | ||

| Eagle 1200 | 39.4 x 59.4 x 27.5 | 50.0 x 69.7 x 26.8 | 3.9~31.5 | More Spec... | ||

| Eagle 1400 | 49.2 x 92.5 x 27.5 | 59.4 x 101.9 x 31.1 | 9.0~36.6 | More Spec... | ||

| Eagle 1400 Plus | 49.2 x 109.0 x 35.4 | 59.4 x 118.5 x 39.9 | 11.8~47.2 | More Spec... | ||

| Eagle 2000 | 68.0 x 108.2 x 39.3 | 79.5 x 126.8 x 53.1 | 17.7~57.0 | More Spec... | ||

Contact us for more info or quote request:

Titan Manual EDM Hole Driller

Economy Line - Hole Size .012"-.118", Programmable Z & W, Blind Hole Depth Control

Titan i25 Series

| Manual machines .008 - 0115 diam, 6" and 14" part thickness | ||||||

|---|---|---|---|---|---|---|

| Model | Tilt | Travels X x Y | Z/W Axis | Market Price Positioning | Value Proposition | |

| i25 Manual / IM | N | 10.0 x 8.0 | 14.0/8.0 | More Spec... | ||

| i25T Manual / IM | Y | 16.0 x 12.0 | 14.0/14.0 | More Spec... | ||

Contact us for more info or quote request:

Titan CNC EDM Hole Driller

Economy Line - Hole Size .010"-.118", XYZ Read Out, Programmable Z, Manual W

Titan i40C/i60C

| Econoline CNC, .008"-.125" diam, 20 " max part Thickness | ||||||

|---|---|---|---|---|---|---|

| Model | Tilt | Travels X x Y | Z/W Axis | Market Price Positioning | Value Proposition | |

| I40C / IM | N | 15.75 x 11.75 | 15.75/15.75 | More Spec... | ||

| I60C / IM | N | 19.75 x 19.75 | 19.75/19.75 | More Spec... | ||

Contact us for more info or quote request:

Titan CNC EDM Hole Driller (US Made)

High Precision - Hole Size .008"-.118", Programmable Z & W, Granite Table & Column

The Full CNC Titan Force serie of machine, is designed and build in the USA. A Granite base construction and Accurate Guide Ways system for accurate positioning. Optional Large tool-changer combined with several options for rotary or rotary tilt table, this machine will match the most demanding production needs. Drill holes from .010 to .125" diam.

Titan Force Series

| Full CNC .008"- .236" diam, 18" Max part Thickness, 18" Z & W axis, Titan CNC, OPT 4th and 5th axis, Toolchanger | |||||

|---|---|---|---|---|---|

| Model | Tilt | Travels X x Y | Market Price Positioning | Value Proposition | |

| Force 30 / US | N | 16 x 12 | More Spec... | ||

| Force 60 / US | N | 24 x 12 | More Spec... | ||

| Force 90 / US | Y | 24 x 12 Head Tilts ± 45° | More Spec... | ||

Contact us for more info or quote request:

Sarix SX Series

Ultra Precision - Min Hole Size .001", Depth Ratio in Carbide 200x Ø, On-Board Electrode Dressing/Inspection

The SARIX Micro EDM machines are designed High Accuracy, Finest Surface Finishes and the greatest Hole Diameter/ Depth Ratio (HDDR) ratio in the industry.

SX Series

| Model | Travels X x Y x Z | Market Price Positioning | Value Proposition | |

| SX80-hpm | 11.81 x 5.9 x 7.87 Table Top | More Spec... | ||

| SX100-hpm | 11.81 x 5.9 x 7.87 Enclosed | More Spec... | ||

| SX200-hpm | 13.77 x 7.87 x 7.87 Enclosed | More Spec... | ||

| SX200-aero | 13.77 x 7.87 x 7.87 Enclosed 6-8 axis | More Spec... | ||

Deep Hole Drilling Package

| Specifically designed for turbine blade drilling and larger parts, full automation using SARIX COBOT | ||||

|---|---|---|---|---|

| Model | Market Price Positioning | Value Proposition | ||

| SX-A344L | Automatic Electrode Feed System | More Spec... | ||

| SX-MDH | Patented Non Contact Magnetic Guiding System | More Spec... | ||

| SX-3d | Micro EDM Milling CAM | More Spec... | ||

Contact us for more info or quote request:

Sarix SX Series

Ultra Precision - 3D EDM Milling, Finish to 2 µ Ra, Orbiting, On-Board Electrode Dressing/Inspection

The SARIX Micro EDM machines are designed High Accuracy, Finest Surface Finishes and the greatest Hole Diameter/ Depth Ratio (HDDR) ratio in the industry.

SX Series

| Model | Travels X x Y x Z | Market Price Positioning | Value Proposition | |

| SX80-hpm | 11.81 x 5.9 x 7.87 Table Top | More Spec... | ||

| SX100-hpm | 11.81 x 5.9 x 7.87 Enclosed | More Spec... | ||

| SX200-hpm | 13.77 x 7.87 x 7.87 Enclosed | More Spec... | ||

| SX200-aero | 13.77 x 7.87 x 7.87 Enclosed 6-8 axis | More Spec... | ||

Contact us for more info or quote request:

Schaublin 632-Y

55° Slant Bed - Roller Ways - Live Tool Turret - Y Axis Fanuc Oi TF +

10.6" Max. Turning Ø - 5,000 rpm A2-4 Spindle - with Xt and E Axis

Model 632-Y

| High Accuracy Package: Thermo-Stabilized Casting, Glass Scales, Spindle Run Out 0.2 µ, C-Axis 12,000 rpm Life Tool, Sub Spin - TailStock Opt. | Roller Ways | |||||

|---|---|---|---|---|---|---|

| Model | Max Ø / Hole | Max Turn Lenght | Turret # Tools Fixed / Live | Market Price Positioning | Value Proposition | |

| 632-Y | 10.6 / 1,259 | 13.7 | 12 / 12 | More Spec... | ||

Contact us for more info or quote request:

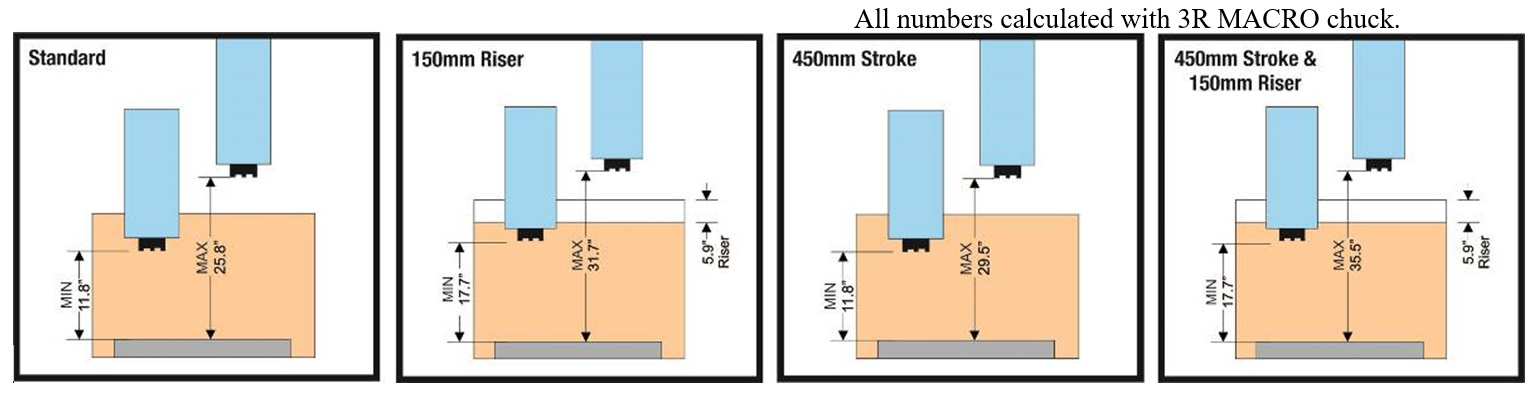

Schaublin 800 Series

45° Slant Bed - Linear Ways - Turret Fixed/Live tooling - Fanuc OiTF

14.1 Max. Turning Ø 4,200 rpm, 6000 rpm, A2-6, A2-5, with 0.5 micron Spin Run-out.

800 Series

| Max Cutting Ø 14.1, Max Length of Cut 15.6 842 / 860 Belt Driven 4,200 rpm spindle & Frontal Turret - 842Mi / 842Mi-Y 6,000 rpm Integral Spindle & Side Turret | |||||

|---|---|---|---|---|---|

| Model | Max Ø / Hole / Length | Turret # Tools Fixed / Live | Market Price Positioning | Value Proposition | |

| 842 A2-5 | 14.1 / 1.65 / 15.6 | 16 / 16 | More Spec... | ||

| 860 A2-6 | 14.1 / 2.36 / 15.6 | 16 / 16 | More Spec... | ||

| 842 Mi | 14.1 / 1.65 / 15.6 | 12 / 12 | More Spec... | ||

| 842 Mi-Y | 14.1 / 1.65 / 15.6 | 12 / 12 | More Spec... | ||

842 / 860 Turret Picture 842Mi / 842 Mi-Y Turret Picture Possible configurations

Contact us for more info or quote request:

Schaublin 100 Series

Flat Bed- Linear Ways - Turret - CNC Fanuc Oi T A2-5 or A2-6 Spindle nose

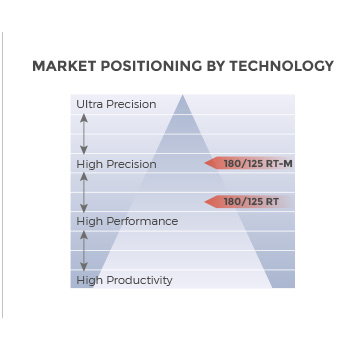

180 CCN Series

| Belt Drive 25/20 Hp - A2-6 4000 rpm - A2-5 5000 rpm - Resolution 0.2 µ - Run Out max 0.2 µ Opt 0.1 µ - Sauter Turret VDI 30 | ||||||

|---|---|---|---|---|---|---|

| Model | C Axis | Max Ø / Hole / L | Turret Capacity Turn/Mill | Market Price Positioning | Value Proposition | |

| 180 RT A2-5 | NO | 13.0 / 2 / 28.4 | 8 / 0 | More Spec... | ||

| 180 RT-M A2-5 | YES | 13.0 / 2 / 28.4 | 12 / 6/6 | More Spec... | ||

125 CCN Series

Flat Bed- Box Ways - Turret - CNC Fanuc Oi TF D1-3 or A2-4 Spindle nose

| Belt Drive 10/7.4 Hp - 5000 rpm - Resolution 0.2 µ - Run out Max 0.2 µ Opt 0.1 µ - Sauter Turret VDI 30 | ||||||

|---|---|---|---|---|---|---|

| Model | C Axis | Max Ø / Hole / L | Turret Capacity Turn/Mill | Market Price Positioning | Value Proposition | |

| 125 RT D1-3 | NO | 10.6 / 1.1 / 10.4 | 8 / 0 | More Spec... | ||

| 125 RT A2-4 | NO | 10.6 / 1.53 / 10.4 | 8 / 0 | More Spec... | ||

| 125 RT-M A2-4 | YES | 10.6 / 1.53 / 10.4 | 8 / 4/4 | More Spec... | ||

| 125 RT D1-3 | NO | 10.6 / 1.1 / 16.1 | Linear Tool | More Spec... | ||

Contact us for more info or quote request:

Schaublin Model 302

CNC Turning - 10 ° Slant Bed - Linear ways - Linear Tool and/or Turret - Fanuc Oi TF

Model 302

| Intregral Spindle - W20 or W25 Collets - 8,000 rpm - C-axis - Run out 0.5 micron | |||||

|---|---|---|---|---|---|

| Model | Max Ø / Hole / Length | Turret | Market Price Positioning | Value Proposition | |

| 302 LT | 7.87 / 0.57-.75 / 7.87 | OPT 12 | More Spec... | ||

| 302 RTM | 7.87 / 0.57-.75 / 7.87 | 12-6/6 | More Spec... | ||

| 302 LT | OPT High Speed Grinding | More Spec... | |||

Tools/Turret/Grinding Configuration

Contact us for more info or quote request:

Schaublin Model 202 TG

Flat Bed - Linear Ways - Turning & OD / ID Grinding Fanuc Oi TF

Model 202 TG

| Intregral Spindle - W20 or W25 Collets - 8,000 rpm - C-axis - Run out 0.5 micron | |||||

|---|---|---|---|---|---|

| Model | Max Ø / Hole / Length | OPT Turret | Market Price Positioning | Value Proposition | |

| 202 TG | 3.2 / .75 / 6.3 | 12-6/6 | More Spec... | ||

| Automation ready from the side/ back of spindle | |||||

Contact us for more info or quote request:

Schaublin Conventional High Precision Lathes

Most commonly used in the Watch making Industry and Micro Mechanic

Small Manual Lathe

| Most Accurate Manual Lathe in the market with 0.5 Micron spindle run out. Spindle nose W12. Direct Drive. Mi model with Integral Spindle | |||||

|---|---|---|---|---|---|

| Model | Bed to Center of Spindle | RPM | Max Ø L/carriage | Between Centers | |

| 70 | 70 mm | 5000 | 5/2.4 | 10.8 | More Spec... |

| 70Mi | 70 mm | 8000 | 5/2.4 | 10.8 | More Spec... |

| 102N | 102 mm | 5000 | 7.8/ 18.5/3.5 | 18.5 | More Spec... |

| 102Mi | 102 mm | 6000 | 7.8/ 18.5/3.5 | 18.5 | More Spec... |

| Lead Screw version (Threading etc.) | |||||

| 102NVM | 102 mm | 3000 | 7.8/ 15.7/3.5 | 17.7 | More Spec... |

Contact us for more info or quote request: